Comparative analysis of rubber synchronous belt and polyurethane synchronous belt

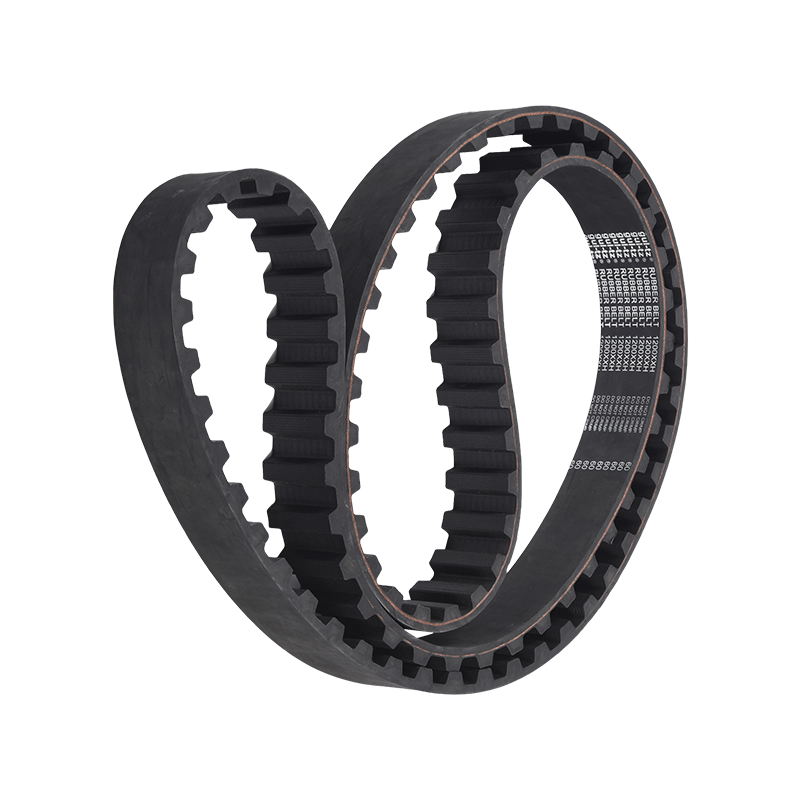

Features of rubber synchronous belt:

1. The rubber synchronous belt has wide use temperature and good flexibility for many times

2. The strength and elasticity of rubber are better

3. The rubber synchronous belt rotates at high speed with little internal heat generation and is not afraid of water

4. The rubber synchronous belt is soft and not wear-resistant

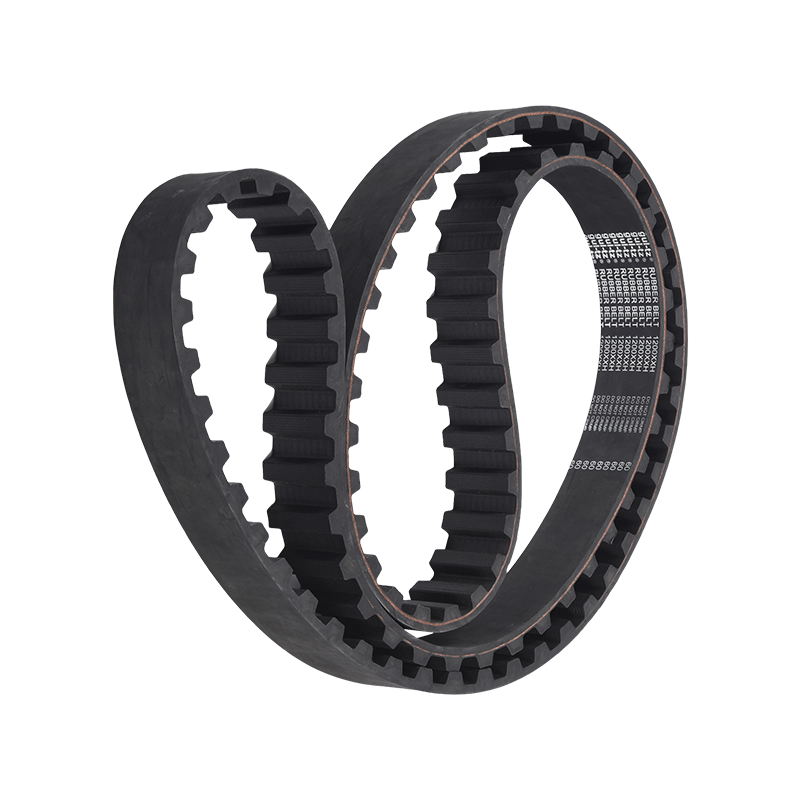

Features of polyurethane synchronous belt:

1. Polyurethane synchronous belt is hard and wear-resistant

2. Polyurethane synchronous belt has better flexibility and is not easy to deform! The weight is also relatively light

3. The polyurethane synchronous belt drive is composed of a circular belt with equidistant teeth on the inner surface and corresponding matching wheels. It combines the advantages of belt drive, chain drive and gear drive. During rotation, the power is transmitted by meshing the belt teeth with the gear slots. The synchronous belt transmission has accurate transmission ratio, no slip, and can obtain a constant speed ratio. The transmission is stable, vibration absorption, low noise, and a wide range of transmission ratios, generally up to 1:10. The allowable linear speed can reach 50M/S, and the transmission power can range from several watts to hundreds of kilowatts. High transmission efficiency, generally up to 98%, compact structure, suitable for multi shaft transmission, no lubrication, no pollution, so it can work normally in places where no pollution is allowed and the working environment is relatively harsh.

Hot Products

-

View More

View More

-

View More

View More

V-belt For Industry

-

View More

View More

T Type Industry Rubber Synchronous Belt

-

View More

View More

Toothed wedge belt

-

View More

View More

Thickened timing belt

-

View More

View More

Open Timing Belt

-

View More

View More

Automotive V-belt

-

View More

View More

Rubber Flat Belt

-

View More

View More

Ribbed Belt

-

View More

View More

Synchronous Pulley

-

View More

View More

Arc tooth industrial rubber synchronous belt

-

View More

View More

Automotive timing belt

English

English 简体中文

简体中文