Uses and advantages of Synchronous Belt

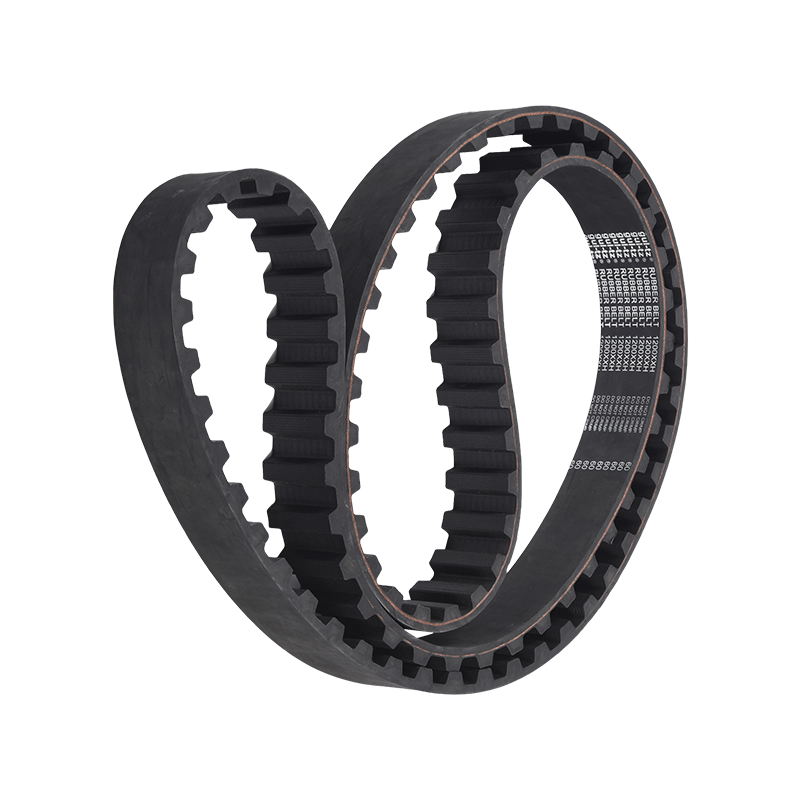

Synchronous belts are a type of mechanical power transmission belt that uses teeth on the belt and corresponding grooves on the pulley to transmit power. They are known for their accuracy in maintaining constant belt-to-pulley speed ratios, which makes them useful in applications where precise timing is important. Some of the advantages of synchronous belts include:

High efficiency: Synchronous belts have a very low slip rate, which results in high power transmission efficiency.

Long service life: Synchronous belts are made of durable materials and are designed to last a long time, which reduces the need for frequent replacements.

Low maintenance: Synchronous belts do not require lubrication, which means they are relatively low maintenance.

Quiet operation: Synchronous belts do not generate significant noise, which makes them suitable for use in environments where noise levels need to be kept low.

Versatility: Synchronous belts can be used in a wide variety of applications, including industrial equipment, automotive systems, and power tools.

Uses include:

Industrial machinery

Automotive power transmission systems

HVAC systems

Conveyors

Robotics

Power tools

Textile machinery

Food processing equipment

Machine tools

Printing presses

Wind turbines

Synchronous belt drives are popular in precision machine tools, robotics, and other applications where precise timing is needed. They are also used in many industrial and manufacturing applications, such as conveying systems, paper and printing presses, and textile machinery.

Hot Products

-

View More

View More

-

View More

View More

V-belt For Industry

-

View More

View More

T Type Industry Rubber Synchronous Belt

-

View More

View More

Toothed wedge belt

-

View More

View More

Thickened timing belt

-

View More

View More

Open Timing Belt

-

View More

View More

Automotive V-belt

-

View More

View More

Rubber Flat Belt

-

View More

View More

Ribbed Belt

-

View More

View More

Synchronous Pulley

-

View More

View More

Arc tooth industrial rubber synchronous belt

-

View More

View More

Automotive timing belt

English

English 简体中文

简体中文