How to use synchronous belt?

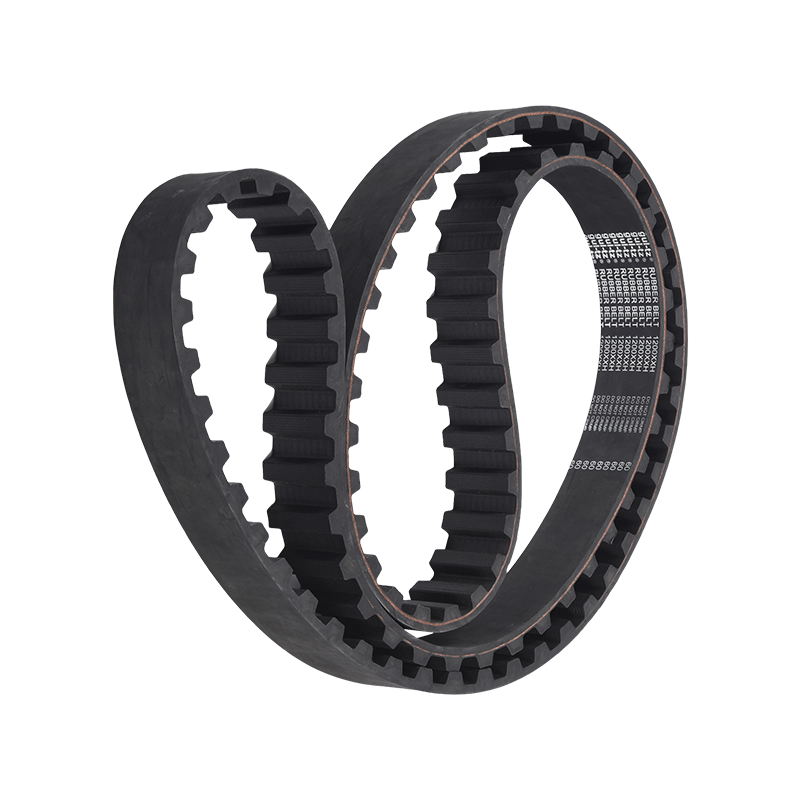

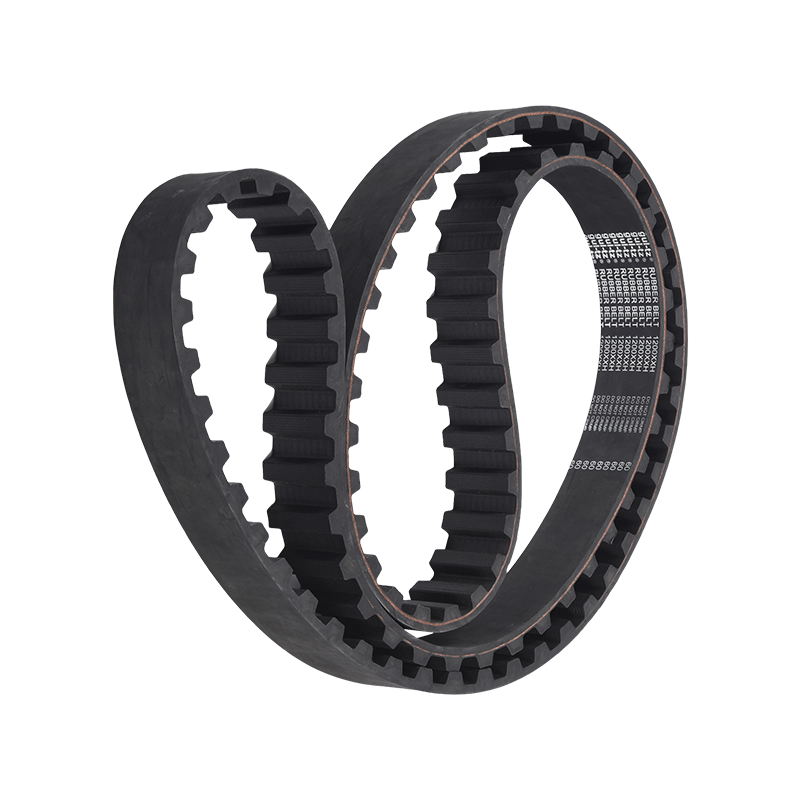

Synchronous belts are a type of power transmission belt that have teeth on the inside surface that engage with corresponding teeth on a pulley to transmit power. They are commonly used in a wide range of industrial applications, from small machines to large manufacturing plants.

To use a synchronous belt, follow these steps:

Determine the correct size and type of synchronous belt for your application. This will depend on factors such as the amount of power to be transmitted, the speed of the pulleys, and the distance between them.

Install the synchronous belt on the pulleys, making sure that the teeth on the belt mesh with the teeth on the pulleys. Use appropriate tools to tension the belt to the manufacturer's recommended tension level.

Ensure that the pulleys are properly aligned. Misaligned pulleys can cause the belt to wear unevenly and can lead to premature failure.

Check the tension of the synchronous belt regularly and adjust as necessary to maintain proper tension. Over-tensioned or under-tensioned belts can cause excessive wear or slipping, which can lead to reduced power transmission efficiency and premature failure.

Replace the synchronous belt when it shows signs of wear, such as cracks or missing teeth.

It's important to follow the manufacturer's instructions and recommendations for your specific synchronous belt, as different types of synchronous belts may have slightly different installation and maintenance requirements.

Hot Products

-

View More

View More

-

View More

View More

V-belt For Industry

-

View More

View More

T Type Industry Rubber Synchronous Belt

-

View More

View More

Toothed wedge belt

-

View More

View More

Thickened timing belt

-

View More

View More

Open Timing Belt

-

View More

View More

Automotive V-belt

-

View More

View More

Rubber Flat Belt

-

View More

View More

Ribbed Belt

-

View More

View More

Synchronous Pulley

-

View More

View More

Arc tooth industrial rubber synchronous belt

-

View More

View More

Automotive timing belt

English

English 简体中文

简体中文