What are the advantages of synchronous pulley?

Synchronous pulleys have several advantages, including:

High accuracy: Synchronous pulleys are designed to maintain a constant speed ratio between the drive and driven shafts, ensuring high accuracy and precision in drive applications.

No slipping: The teeth on the pulley engage the teeth on the belt, which eliminates slipping and ensures a positive drive.

Increased efficiency: The positive engagement between the pulley and belt reduces energy loss and increases the overall efficiency of the drive system.

Longer belt life: The positive engagement between the pulley and belt reduces the wear and tear on the belt, resulting in longer belt life and less maintenance.

Reduced vibration: The positive engagement between the pulley and belt reduces vibration, which can improve the stability of the drive system and extend the life of other components.

Higher load capacity: Synchronous pulleys have a higher load capacity compared to traditional pulleys, which makes them ideal for demanding drive applications.

Easy installation: Synchronous pulleys are easy to install and do not require any special tools or machinery.

Overall, synchronous pulleys offer several advantages over traditional pulleys, including improved accuracy, increased efficiency, longer belt life, reduced vibration, higher load capacity, and easy installation.

Hot Products

-

View More

View More

-

View More

View More

V-belt For Industry

-

View More

View More

T Type Industry Rubber Synchronous Belt

-

View More

View More

Toothed wedge belt

-

View More

View More

Thickened timing belt

-

View More

View More

Open Timing Belt

-

View More

View More

Automotive V-belt

-

View More

View More

Rubber Flat Belt

-

View More

View More

Ribbed Belt

-

View More

View More

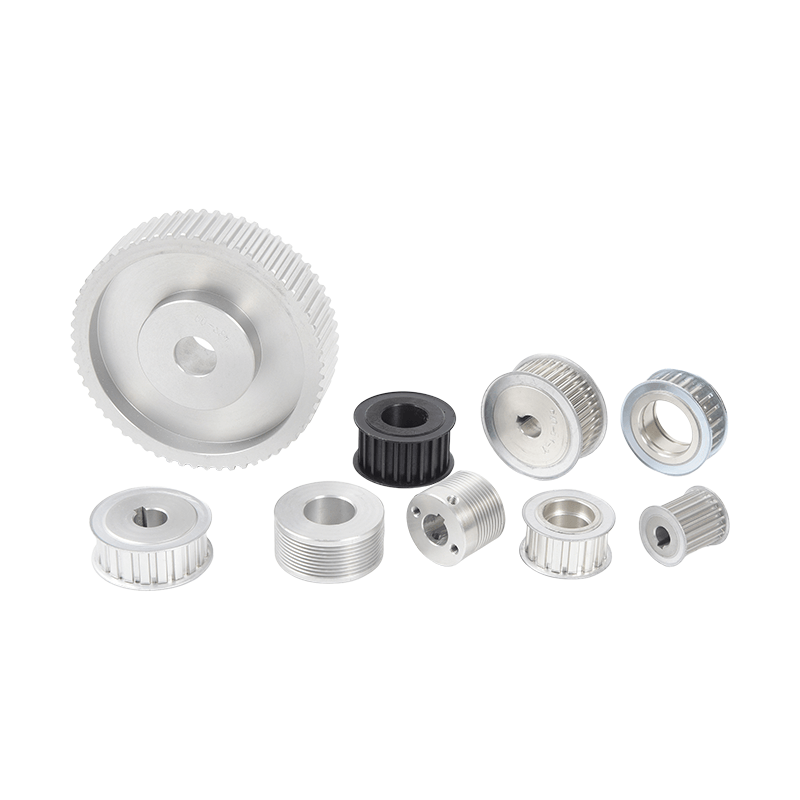

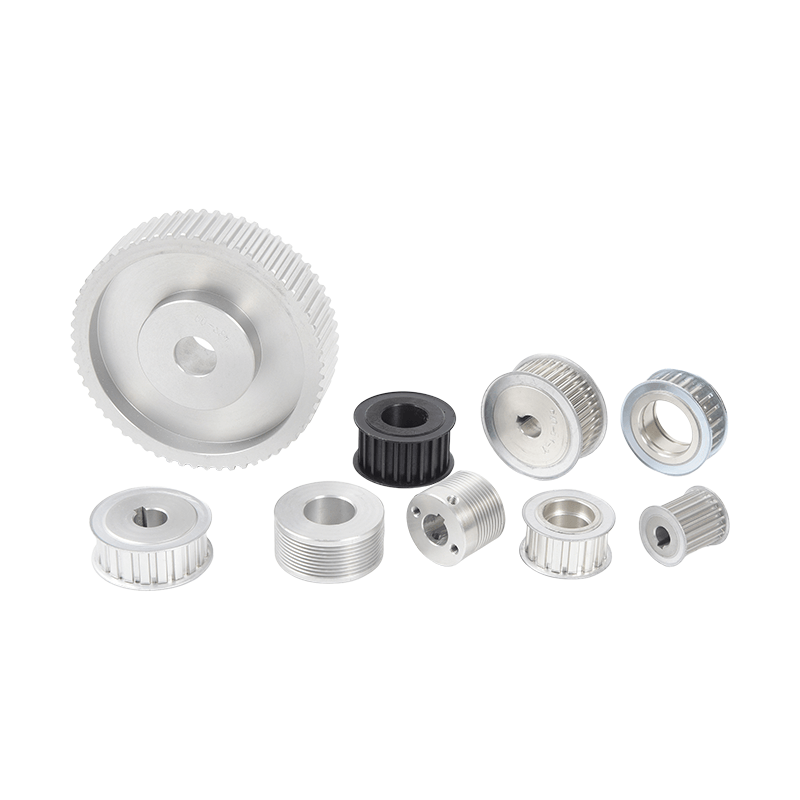

Synchronous Pulley

-

View More

View More

Arc tooth industrial rubber synchronous belt

-

View More

View More

Automotive timing belt

English

English 简体中文

简体中文